Over 15 years of experience in windows, doors, and UPVC

Your Vision, Perfected in Every Window and Door

Enhancing your spaces with Premium uPVC windows and doors.

Nafeza FZ LLC

Nafeza was established in 2009 and has developed its business over 15 years in the sectors of windows, doors, and homogeneous panels (uPVC).

Our first branch was established in Alexandria, Egypt, and our latest branch has been opened in the

industrial area of Ras Al Khaimah, UAE.

Our company is continuously developing and expanding within the UAE and aims to grow across the Gulf

and the Middle East.

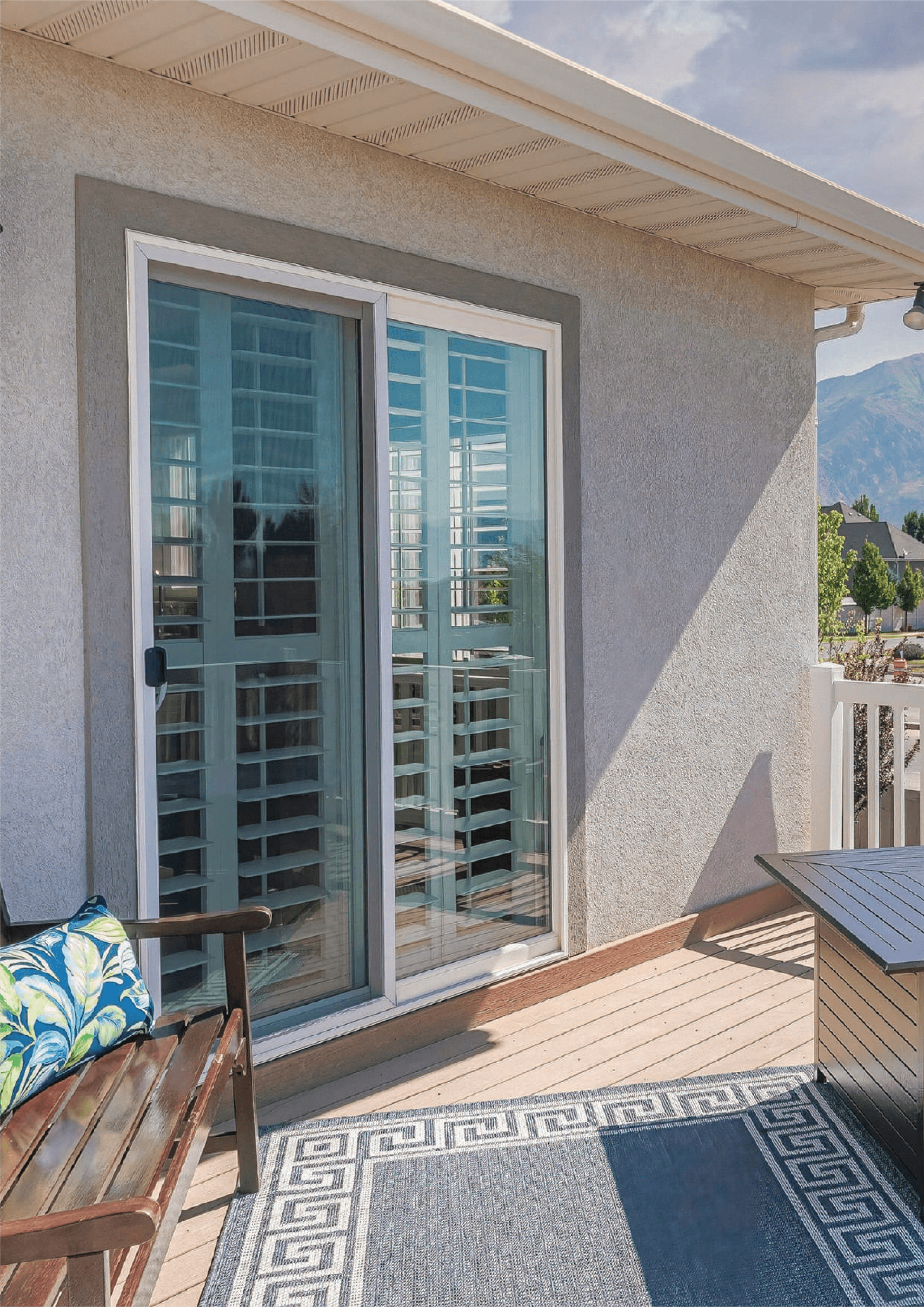

Tilt Slide System

Lift Slide System

Smart Slide

Folding System

Arched Doors

Tilt And Turn System

Casment Doors

Casement Windows

Winter Garden

Insect/Flyscreens

Shutter

Window & Door Fittings

Lamination Colors

Top Products

Our product’s flexibility in shaping to suit the desired design allows endless design possibilities for

designers and architects, accommodating angles, curves, and arches that unleash the designer’s

imagination to create outstanding artistic work.

VISION

Our goal is to expand within the UAE and throughout the Gulf and the Middle East, and to increase customer awareness of the best products crafted with skilled hands.

Nafeza also aims to bring to life the creative technical ideas envisioned by our clients, delivering products and services that meet their satisfaction.

Services

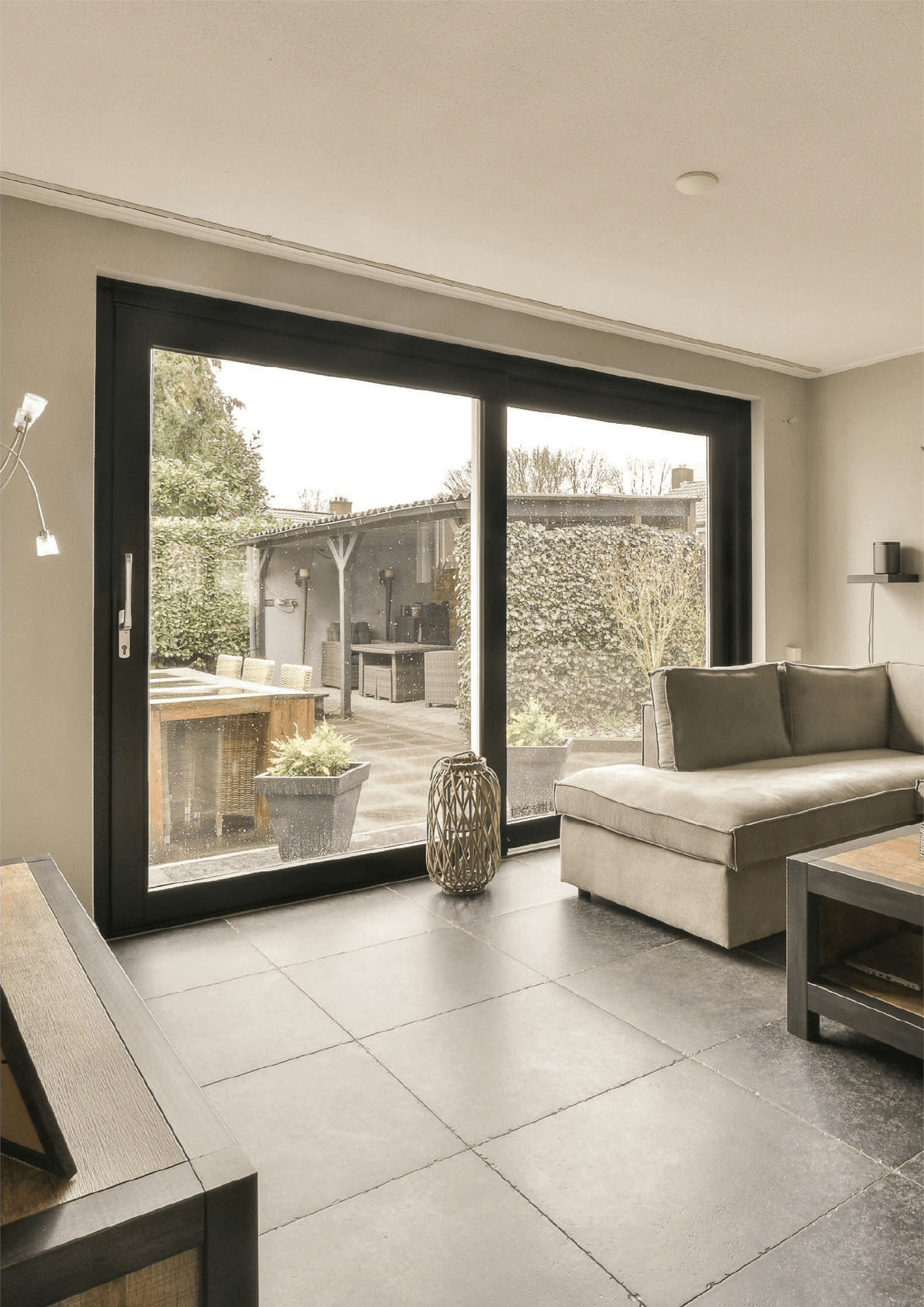

Reasons to Choose Us

- Our product’s flexibility in shaping to suit the desired design allows endless design possibilities for designers and architects, accommodating angles, curves, and arches that unleash the designer’s

imagination to create outstanding artistic work. - The product’s durability and color stability withstand strong sunlight and high temperatures in the UAE and the Middle East.

- It also provides protection against intrusions due to the many enhancements in the sector’s mechanical devices, making it difficult to penetrate.

- The outer side of the frame and sash is distinguished by its smooth curved surfaces, thanks to the precision in manufacturing the sector.

- The angles within the frame’s cavity and the outer side of the sash meet precisely and securely due to the unique arches and design system, ensuring the strength and durability of the product in its

movements. - One of the notable features is the five-degree angle of the sector cavity, which expels rainwater to the outside, preventing it from coming into contact with the internal mechanical steel supports.

- We offer uniquely styled sectors, such as Andalusian, Roman, European, and Arabic styles.

- Our product is manufactured using a modern global system from a German production line.

| Heat Transfer Rate (w\sq.M) | Used Sectors |

|---|---|

| 1.6-1.5 | Wooden sectors - Thickness 60mm |

| 5.2-5.8 | Aluminum sectors without heat barrier |

| 3.9-2.9 | Aluminum sectors with heat barrier |

| 2.4 | uPVC sectors with 2-3 chambers |

| 3 | Single glass 4-6mm |

| 2.2-2.1 | Double glass with 12mm spacer |

| 4.5 | Triple glass with 12mm spacer |

- We provide window and door sectors in white from the outside, with the option of choosing different interior colors.

- The product also features various opening and closing systems, giving you the freedom to change the systems for doors and windows while maintaining efficient sealing.

- It helps in sound insulation from the external world, protecting you from external noise.

- Our product is manufactured using a modern global system from a German production line.